INNOVATIONS

![edit pic [ masked group ]](https://www.nipsea.group/wp-content/uploads/2021/11/edit-pic-masked-group--1024x439.png)

Dr. Hong Jiang

Dr. Hong Jiang

Chief Technology Officer of NIPSEA Group

Greenhouse effect, resource scarcity, environmental degradation, we are in a world full of change and volatility. Innovation is the only way to address the unprecedented challenges our world is facing. In the 140-year long history of Nippon Paint, innovation has been the cornerstone that empowers us to meet customer demands with superior solutions. With the brand promise of innovation with heart & people at our core, we are inspired by you to imagine technologies that transcend the ordinary.

NIPSEA Group’s R&D Innovation Centre in Shanghai is our gateway to customer-inspired innovations. The Centre houses more than 150 experienced professionals across various fields and serves as a knowledge hub. We are building a campus in the R&D Innovation Centre in Shanghai, in which we aim to employ more than 300 R&D and Innovation professionals by 2025. We also have an R&D Centre in Singapore that focuses on colour technology innovation, primarily serving the Association of Southeast Asian Nations (ASEAN) market.

Nippon Paint Singapore has developed a total cool paint solution with IR infrared-reflective technology to reflect infrared radiation from the sun into the atmosphere and away from the horizontal surface (roof, road perimeter) and vertical (facade) surface of the building. This will reduce thermal heat accumulation at the surfaces to cool down the buildings by up to 5°C.

NIPSEA Group has created a new-generation automotive refinish waterborne production line N-MAX. With exclusive rheological technology, N-MAX increases the spraying efficiency in wet-on-wet painting which shortens the operation time.

MonoShineTM is high-solid waterborne technology that is environment-friendly as it provides a rapid coating process and also reduces VOC emission substantially. Unlike the conventional coating system, MonoShineTM combines primer, basecoat and clearcoat into a single film and still maintains high gloss and excellent appearance by using a unique crosslinking system.

Compared to the conventional WB 3C2B technology, IPP (Integrated Painting Process) technology is more economical and environmentally friendly due to less energy consumption and lower VOC emission resulted from its unique “Wet on Wet” process between the coating layers of primer (BC0) and basecoat (BC).

A key step in NIPSEA Group’s commitment to a green future is realised by the successful commercialisation of our waterborne polyacrylate dispersion resin platform. With the aim of reducing solvent emissions, improving air condition, and bringing a healthier home to everyone, NIPSEA Group has been providing waterborne paints and coatings to the world for many years. Building on years of dedicated research, NIPSEA Group has gone one step further: In 2021,we have successfully commercialised a resin platform of waterborne polyacrylate dispersion. This raw material platform provides new technology, new material, less solvent, and better performance to many of our coatings. This new waterborne resin platform builds on the success of our waterborne polyurethane dispersion platform, and has greatly improved our in-house waterborne resin capability. It has also formed the foundation of our transition from solvent-borne coatings to waterborne coatings.

One of NIPSEA Group’s most exciting new developments, the ACECRON® 130TF E-coat, is an industry-leading electrophoretic paint that cures at 130°C without the addition of heavy metals such as lead and tin. ACECRON® 130TF provides excellent film appearance, workability, bath stability and outstanding corrosion resistance. It has been successfully adopted by one of China’s largest compressor providers. It helps customers to reduce energy consumption and increase productivity without oven upgrading and reconstruction. ACECRON® 130TF E-coat achieves REACH and RoHS Compliance and helps meet the requirements of customers all over the world.

The key to achieving both aesthetics and low carbon emissions is through the alternative use of “bio-based” materials. The use of oil as a medium for most paints has been in practice for over 2000 years, with tung oil being used as a film-forming agent by China to blend various colours and form coatings. However, the traditional natural collection of raw lacquer has become inadequate in the industrial era. The addition of curing agents has become an inevitable choice for the development of the automotive industry. This technology is based on the use of petroleum as a raw material, leading to pollution from the waste paint films which cannot be degraded easily.

To upgrade our technology, we must first address the biggest “pain points”. In recent years, NIPSEA Group has focused on the “Renaissance” bio-based technology. As a representative of its global technology integration, NIPSEA Group has selected some bio-based curing agents developed by Covestro in Germany as the foundation to develop a new generation of automotive coating solutions.

NIPSEA Group has innovatively used bio-based curing agents that contain nearly 70% of bio-based raw materials instead of petroleum-based curing agents. The bio-based curing agents can be converted into final products through biological or chemical transformation, effectively reducing carbon emissions during the production process. With its profound technological accumulation, NIPSEA Group quickly applied bio-based technology to the research and development of varnishes and ultimately formed the final product through deep integration of large formulations and industrial manufacturing.

This is the real innovation behind the environmental protection of NIPSEA Group’s bio-based coating solution: achieving environmental protection goals without compromising performance. In laboratory tests, NIPSEA Group uses bio-based varnishes that remain stable in hardness, appearance, ageing tests, and chemical resistance tests, and even exhibit better performance in some tests.

Clear Shield®, Virus Clear & Health Shield, an antimicrobial technical solution offers a total solution to our living environment’s continuous Safety & Protection. With nearly a decade’s continuous efforts in R&D, from VirusGuard® to Protecton®, NIPSEA Group Technology has developed a series of coating & paints products in the region.

Nippon Paint Malaysia’s introduction of the country’s first Child Wellness Range, a series of functional coatings that focuses on enabling clean air, safe touch and creativity in 3 key growth milestones. Its paint solutions are water-based, lead and mercury-free with low Volatile Organic Compound (VOC) as well as Total Volatile Organic Compound (TVOC) emissions, which is safe for the environment as well as indoor spaces.

The R&D team in Nippon Paint has developed innovative coating solutions to address the surface challenges from composites substrates. With NP SPARLITE®, our portfolio of composites coating products, we can solve the low surface quality issues of various composites substrates, offer a great deal of design freedom, in terms of surface appearance effects and coating process versatilities, and help composites materials in a wide range of market applications.

TuffLac——a scratch resistant yet healable clear coat has been developed while several in-house technologies have synergistically boosted its scratch resistance without compromising the appearance, mechanical properties and applicability.

At Nippon Paint, CyGLAZ® technology has been incorporated into the clear coats of BeudLac and TuffLac, producing a superior coating that protects your car against various environmental factors with long lasting gloss retention.

Colour Technology is committed to leading research and innovation on colour material, colourant, and colour science. It seeks to render colour diversity and differentiation while reducing VOC emission, energy consumption, and significantly improving productivity. By creatively designing and employing versatile colour materials, NIPSEA brings more colours to the world. We have developed 10 colourant platforms which have revitalised traditional offering portfolios, and also provide a powerful impetus to enable green technology and colour innovation across a variety of application areas such as automotive coatings, general industrial coatings, coil coatings, and decorative paints. The integration of flourishing artificial intelligence with colour science in 2021 has presented an opportunity to transform traditional colour matching into a data-driven process than can better meet the needs of our customers.

We are proud to announce that NIPSEA Group has set a new benchmark in the field of automotive paint segmentation by officially obtaining the global certification of BMW waterborne paint. This makes us the world’s leading supplier of automotive paint to receive official certification from the BMW Group, winning product certification for the relevant five colours at once.

Currently, white has already been mass-produced at the BMW Munich factory in Germany, and blue and black will also be applied to the mass production of X3, 5 series, X5, and other models at the Brilliance BMW NEX factory. This marks the official start of our cooperation with BMW Group on IPP waterborne paint products and demonstrates our automotive paint R&D strength and cutting-edge resources recognised by international automotive brands represented by BMW. This new certification will provide strong revenue for our global automotive paint business and bring breakthroughs and growth to the booming Chinese market.

As one of the leading enterprises in the automotive industry, BMW Group has independent testing standards and detailed comprehensive testing requirements for global certification. We are proud that our product has met these high-quality standards, ensuring that we can supply high-quality products that meet the demands of BMW customers’ continuous improvement with our high-level quality specifications and core technologies.

We have continued to improve our technology, process, aesthetics, service, and other aspects in the face of rapidly changing new trends and demands in the automotive paint market. Through years of dedicated development and continuous optimisation of our product system, we have been able to fully meet the quality requirements of BMW and provide excellent coating performance such as chip resistance and UV resistance. Our IPP process helps reduce paint consumption during the coating process, achieving the effect of reducing comprehensive costs and energy conservation and emission reduction, fully responding to the national “dual carbon” goal. This global certification of BMW waterborne paint will inject new momentum into our competition in the automotive paint market.

With the gradual full production of the BMW Lydia factory and the increase of new production lines of Brilliance BMW NEX factory, we expect the market scale of IPP waterborne paint to further increase. Our global certification of BMW waterborne paint not only means that we have successfully expanded our market share in the European and American automotive markets but also that we will soon achieve a share breakthrough and organic growth in the Chinese market.

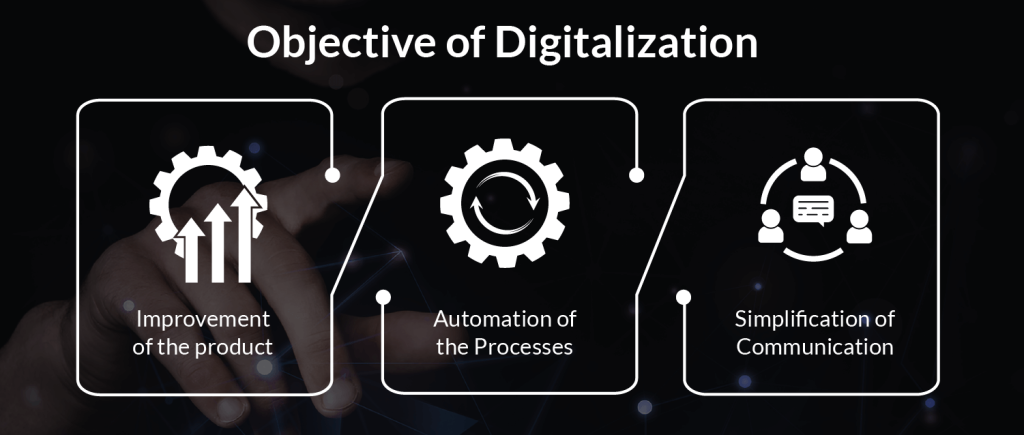

Digitalization is to enable or improve processes by leveraging digital technologies and digitized data. In a world full of changes and volatilities, digitalization is a useful tool and methodology to help us increase productivity and efficiency while reducing costs. Digitalization is critical in the whole process of our innovation. It empowers us to improve the products, automate the process and simplify our communications.

Tools in our Digitalization

Project portfolio management (PPM) provides visibility into demand, resources, and project portfolios to improve productivity in our innovation from concept and feasibility test to commercialization.

Electronic Lab Notebook helps to run labs more efficiently and maximize research output. Lab managers and scientists seamlessly plan and document experiments, track progress, and share results with ease and security protection.

With the help of the Intellectual Property Management System, we can manage and maintain intellectual property-related documents and automate processes for securing intellectual property rights.

In April of 2021, Nippon Paint announced to team up with HRC (Hengrui Corporation) to co-develop innovative composite coating solutions. This cooperation will accelerate the commercialization of CFRP in Auto and other industries.

NIPSEA Technologies and the Agency for Science, Technology and Research (A*STAR) announced to have joined forces in the field of coating solutions for autonomous navigation. This collaboration develops coating solutions for C.A.S.E. (connected, autonomous, shared and electric mobility).

Collaboration with all the partners in the industry chain is crucial to innovation. In the past few years, we have developed strategic relationships which help us to introduce advanced materials to develop more environment-friendly and highly efficient coating solutions for a sustainable future.

We are looking forward to invest in innovative start-ups and scale-ups with new technology, solutions and mindset which will help to shape the future of the industry.

Criteria of assessment:

- Strategic emerging industries.

- Technology and business to disrupt the existing value chains.

- Strong market potential and growth momentum in the next 5-10 years.